Making Customers Look in Proportion, Even if They Aren’t Born That Way

Simon Skottowe

Stepping into Simon Skottowe’s shop, not far from the Hungarian Parliament, one enters a world of immaculate suits, shirts, ties and all the trappings of an exclusive London club.

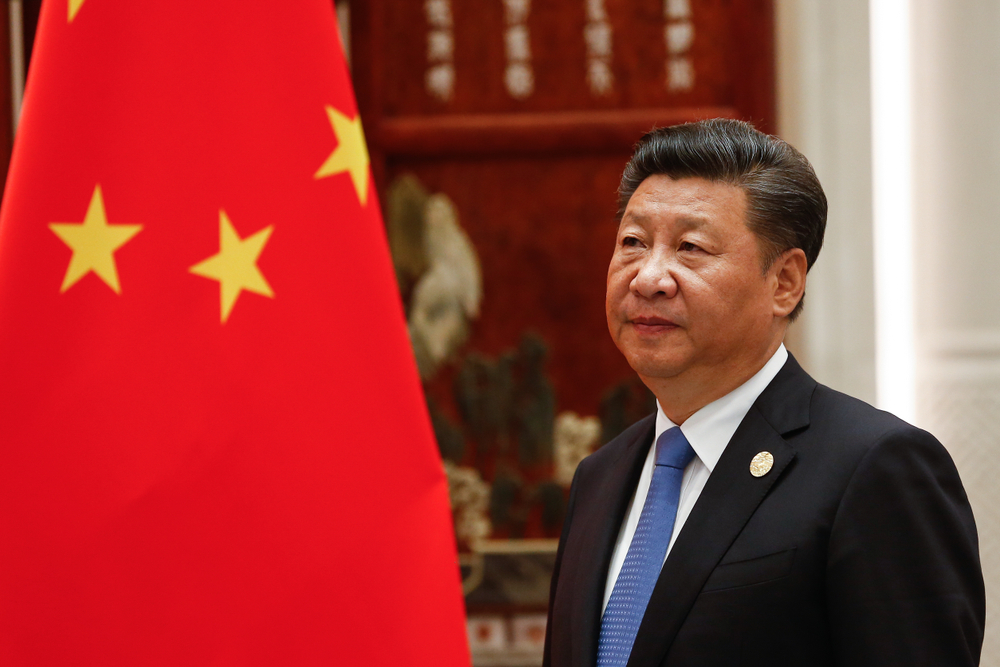

This being one of the last hot days of September, your correspondent, in shorts, a t-shirt and an aging, made-in-China safari waistcoat, felt embarrassingly under-dressed.

Skottowe’s Facebook page introduction line is: “The ultimate in luxury menswear, both bespoke and specialist ready-to-wear.” But if this bespoke tailor had any disdain for journalists with the fashion tastes of a 1970s barbarian, he certainly didn’t show it.

Not that it’s always been like this. Little more than a decade ago, “we were working in pretty tiny” premises in Budapest’s District VI, where “you couldn’t swing a kitten, let alone a cat,” the bearded tailor candidly admits as we sink into comfy armchairs, coffee being served.

Skottowe finished a decade-long stint in Milan to arrive in Budapest in 1998 as the design chief for the former Vörös Október Férfiruhagyár, a striking name to have on one’s CV, meaning “Red October Men’s Clothes Factory.”

Re-christened Elit Clothing by the then-new British owners, its 1,700 workers spread out across five sites in Hungary cut, sowed, pressed and despatched 12,000 suits a week.

“This was the first time I’d worked for a really big company. Most of the clients were British High-Street companies, like Moss Bros and Cecil Gee [...] so it was, sort of slightly better than average industrial tailoring,” he recalls.

But three years on, having just put down the deposit on an apartment in Budapest, a round of corporate cost-cutting saw the designer-in-chief made redundant. He could return to his beloved crafting world of bespoke tailoring in the Hungarian capital as a sole freelancer, but that would take courage.

Daring to Win

Skottowe dared, and arguably against the odds, has won. Today, he employs three sowers and two part-time assistants.

“So it’s not a tiny operation, though it’s not massive. By comparison [to Elit], you can knock off all the zeros on the 12,000 suits, plus something else, because what we do is more or less completely handmade,” he says.

And with his suits routinely retailing at around EUR 3,500, inevitably, his clients tend to be relatively wealthy. It’s all rather anonymous, however.

“It’s not done to give names, but I can say our clients include owners and directors of some of Hungary’s well-known, historical and most successful companies, senior people in finance, banking, top lawyers, some from Austria, Switzerland, Germany,” he reveals when pressed. Naturally, in 2001, it didn’t start out that way.

“At that point, it [marketing] was mostly the ex-pat community, word of mouth, friends of friends,” he acknowledges. He remembers BBJ mixers around the early millennium.

“Oooh, weren’t they lovely in the good old days! But for a certified introvert, BBJ mixers were something more like torment than fun, not my cup of tea at all, though I’ve got better at it over the years,” he says. Slowly but surely, his perseverance, dedication and innovation paid dividends.

Such professionalism was, of course, not acquired overnight. Skottowe had started young. His mother, perhaps desperate to keep two young sons out of harm’s way on holiday in England, gave them “a couple of tapestries to do [….] I don’t know what went through her mind, boys sowing,” he says.

But before she knew it, young Simon was hooked. By 13 or 14, he was making things for family and friends and reaping rewards.

“I got into making curtains in a big way, English-style curtains, with linings and pattern-matching fabrics [...] It was a good little money-earner; I had a very solid bank account back in those days for a 13-year-old!” he chuckles.

Soaking up Skills

His course set, Skottowe left school to study at Harrow College of Art and Design, where he soaked up skills and knowledge from his tutor, a former Savile Row tailor.

However, in 1988, though armed with a degree and significant practical experience, bespoke tailoring was going through hard times, even in London.

“Everybody was wanting Versace and Armani suits. Savile Row was seriously suffering,” he recalls. And so, like many others at the time, Skottowe packed his bags and flew to Milan to try his luck. In Italy, he gained more experience, learned the vernacular and picked up scores of contacts.

“I got into pattern cutting and tailoring for manufacturers working for Katharine Hamnett, a famous designer in London, but with her production in Italy,” he says.

This all proved invaluable when, after being headhunted for the Elit job, he later found himself starting out alone once more in Budapest, where the craft of hand tailoring was still recovering from the mass-production mindset of the communist era.

“You don’t have the suppliers here from whom you can easily get stuff [of the right quality], but from working in Italy with the bigger companies, I know how to approach them. I’m trying to buy rolls of 50 meters of canvas, which is, for them, absolutely nothing, but because they know what we do, and they respect it, the camaraderie kicks in, and it’s all sorted,” he says. The challenges even come down to items like buttons.

“There is no supplier of high-quality buttons; they don’t exist. You have to import them from Italy, or via wholesalers in the U.K., or buy them in Vienna. You can’t just put synthetic buttons on a EUR 3,000 suit.”

Despite the hurdles, the satisfaction of helping to recreate an all-but-lost craft industry, even if only in a small way, is a reward in itself for those like Skotttowe, who delight in the world of high-quality fabrics and the finest of cuts.

And in this ever faster-moving world, there is no chance for any Johnny-come-lately out for quick success in bespoke tailoring.

“If there’s a problem with a textile, it’s twisted, shrinking, [….] how to make the fitting on the customer properly, so as to make the best of their good features, make them look in proportion, even when they aren’t [.…] This all really takes an enormous accumulation of knowledge and skills. You can’t pick that up in six months.”

Go Bespoke For the Environment

It may not be the foremost reason his customers have in mind when ordering custom-made clothes, but bespoke tailoring is environmentally good for you, Skottowe enthuses when the subject is raised.

“The clothing business is one of the most polluting in the world. This is partly due to the preparation of the materials [including the dyes], but largely because of the many unsold garments from fast-fashion lines that are now creating huge waste issues,” he says.

In stark contrast, a uniquely made, bespoke garment is ordered, carefully cut, and sold, creating far less wastage. Moreover, the construction techniques of high-quality tailoring mean that this suit will last as much as eight or even 10 times longer than an average quality, confection-made garment.

“Consequently, the pollution and wastage created by one high-quality bespoke suit is about one-fifth to one-tenth of that created by confection garments worn over the equivalent period,” Skottowe argues.

This article was first published in the Budapest Business Journal print issue of November 3, 2023.

SUPPORT THE BUDAPEST BUSINESS JOURNAL

Producing journalism that is worthy of the name is a costly business. For 27 years, the publishers, editors and reporters of the Budapest Business Journal have striven to bring you business news that works, information that you can trust, that is factual, accurate and presented without fear or favor.

Newspaper organizations across the globe have struggled to find a business model that allows them to continue to excel, without compromising their ability to perform. Most recently, some have experimented with the idea of involving their most important stakeholders, their readers.

We would like to offer that same opportunity to our readers. We would like to invite you to help us deliver the quality business journalism you require. Hit our Support the BBJ button and you can choose the how much and how often you send us your contributions.

.png)