Embracing Industry 4.0: Free Your SME From the ‘Excel Monster’

Photo by Zapp2Phot / Shutterstock.com

Hungarian SMEs can have a hard time finding resources for development, including digitizing their manufacturing business. Catching up with multinational companies is just as difficult, yet it is far from impossible.

When it comes to integrating the latest digital technologies in manufacturing, the gap between multinational companies and Hungarian small- and medium-sized enterprises remains vast.

The reality is that most domestic SMEs are still in the Industry 3.0 phase and are considering an upgrade to 4.0 at best. The past few years haven’t helped. There were few funds up for grabs from calls for proposals, skyrocketing interest rates made taking out corporate loans prohibitively expensive, and company bosses still shudder when you mention the spike in costs during the energy crisis.

However, it is no longer a nice option for manufacturing businesses to embrace cutting-edge solutions. It is becoming a matter of survival. Ferenc Nyírő, industrial digitalization business unit manager at Kontron Hungary, says fundamental factors hamper the operation of local SMEs. For starters, product development is not digitized.

“Without sophisticated product lifecycle management, the digital leap won’t happen.”

A state-of-the-art PLM presumes the existence of a digital thread that follows the entire process of product management, manufacturing and servicing. Productivity is at stake here, as evidenced by the fact that hourly production in neighboring Austria is 74% higher than in Hungary. It takes a comprehensive audit to assess what must be done to narrow that gap.

One issue Nyírő identifies is that many businesses still rely on Excel, for example.

“Fair enough, you can do many things with Excel, but it’s an offline tool, and it doesn’t know anything about manufacturing processes,” he points out. “The worst part is when one person at a company builds this ‘Excel monster,’ around which the whole production revolves; when he leaves, everything crumbles.”

The Best can do Better

Even those SMEs that produce for export markets can improve productivity significantly, Nyírő argues.

“Imagine if they introduced robust digital solutions, how much that would boost their global competitiveness,” he suggests. Training also comes into the picture, and even though it is a low-hanging fruit, it is typically underrated. It is also crucial to go one step at a time.

“You can’t just jump too big all at once,” Nyírő points out, emphasizing that industrial digitalization must factor in reality. Local SMEs just don’t have the right size to implement change of that scale. Nyírő gives the example of Bosch, where 3D design for simulation and manufacturing has been standardized, as a result of which working hours can be cut by 40%. Since design itself eats up half of the total working hours, this is a vast advantage.

“Bosch has a lot of people on projects like that, whereas SMEs would need time and resources to get the same done,” Nyírő says.

For the sake of process optimization, his company combs through every manufacturing step to develop proposals for improvement. A document of up to 100 pages is then prepared to outline a road map for change so every client can receive a tailor-made transformation action plan.

Apart from such audits, the supplier development programs of MNCs can fast-track SMEs to success. But Hungarian SMEs typically embrace one of two approaches: either they are developing or aiming for survival.

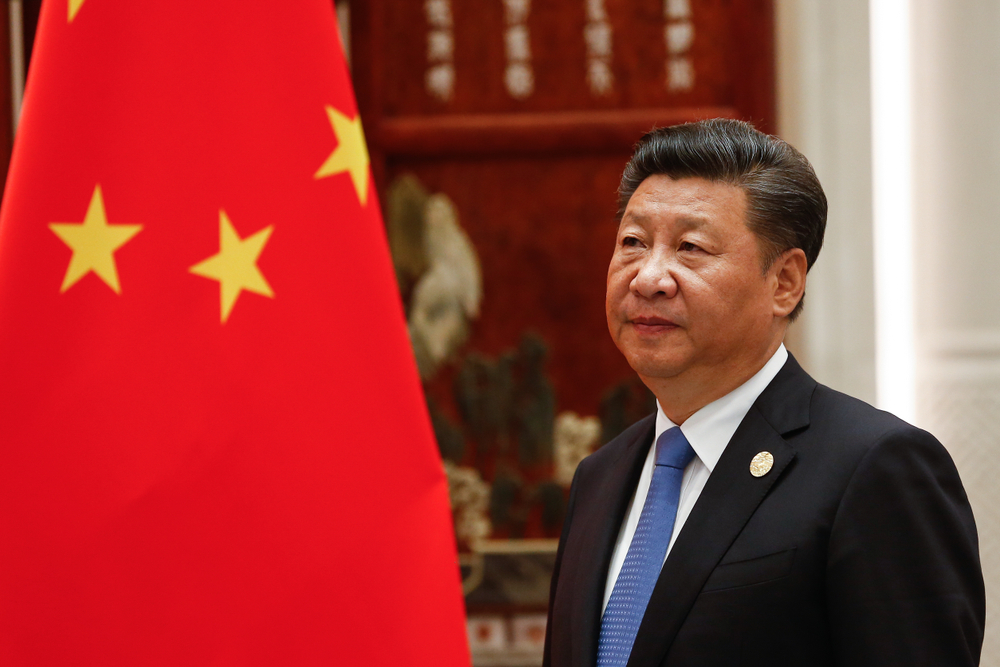

COVID and the energy crisis taught them not to take anything for granted. Geopolitical tensions, like the war next door in Ukraine and the conflict in the Middle East that is now impacting Red Sea shipping, can turn any business plan upside down overnight.

“When you start planning even near-term, you need to add a risk coefficient,” Nyírő says.

Sustainability Costs

The need to comply with an ever-more stringent legal framework at the EU level further raises costs. Sustainability is pushing its way to the fore, not least because of mandatory ESG reporting, while stakeholders also expect elevated IT security measures.

Such extra expenses can divert resources from digitization. Yet, they should be considered opportunities since businesses (and the whole economy) will become more crisis-proof in the long run.

Finally, Nyírő mentions the quick emergence of AI-driven applications. AI relies on data, and it would be great to have information from all kinds of best practices. However, companies are reluctant to share their own findings as they fear competition. Therefore, company-specific data tends to be used for training AI tools.

“It’s incredible that, within one year, all related products have an AI feature when it comes to digital manufacturing,” Nyírő notes. “Simulation, for instance, can be accelerated to a large extent if you have the right training data.”

The ultimate task is first to turn data into Big Data and then Big Data into Smart Data, as only the latter represents an actual business value. Smart Data can be used for decision-making in the form of insight or foresight; it is easy to understand and interpret and enables imminent intervention.

SMEs willing to embrace digital transformation in manufacturing must be clear on that, as well as the fact that it isn’t enough simply to say you want to move to Industry 4.0. Setting the purpose of its adoption is even more critical.

This article was first published in the Budapest Business Journal print issue of February 23, 2024.

SUPPORT THE BUDAPEST BUSINESS JOURNAL

Producing journalism that is worthy of the name is a costly business. For 27 years, the publishers, editors and reporters of the Budapest Business Journal have striven to bring you business news that works, information that you can trust, that is factual, accurate and presented without fear or favor.

Newspaper organizations across the globe have struggled to find a business model that allows them to continue to excel, without compromising their ability to perform. Most recently, some have experimented with the idea of involving their most important stakeholders, their readers.

We would like to offer that same opportunity to our readers. We would like to invite you to help us deliver the quality business journalism you require. Hit our Support the BBJ button and you can choose the how much and how often you send us your contributions.